(HPP) TECHNOLOGY

How does it work?

HIGH-PRESSURE PROCESSING (HPP) TECHNOLOGY

At Ventolini, we are pioneers in Colombia in the implementation of High- Pressure Processing (HPP) technology for beverages and ready-to-eat foods. This key innovation integrates food safety, quality and nutritional value preservation, clean-label formulations, and sustainability—reaffirming our commitment to the development of responsible foods aligned with the future of the industry.

1. Maximum food safety:

Inactivates pathogenic microorganisms such as Listeria monocytogenes, Salmonella, and E. coli, reducing the risk of foodborne illnesses without affecting product integrity.

2. Extended shelf life:

Significantly prolongs shelf life, maintaining freshness and microbiological stability, optimizing logistics and reducing waste.

3. Preservation of nutritional value:

As a non-thermal process, it preserves vitamins, antioxidants, enzymes, and bioactive compounds sensitive to heat.

4. Superior sensory quality:

Maintains original flavor, aroma, and texture, offering a fresh product experience.

5. Reduction or elimination of preservatives:

Enables cleaner formulations (clean label), aligned with natural consumption trends.

6. Process versatility and sustainability:

Applies to a wide variety of foods, improving industrial efficiency and reducing energy and water use compared to traditional thermal methods.

They represent a new generation of practical, healthy, and technologically advanced nutrition. This portfolio consists of complete and balanced meal preparations that integrate high-quality proteins, grains, and fresh vegetables, carefully selected and combined to deliver an optimal nutritional experience— without compromising flavor or quality.

Each recipe is made with 100% natural ingredients, free from chemicals, preservatives, or artificial additives, and is subsequently processed using High-Pressure Processing (HPP) technology, ensuring months of shelf life while preserving its original sensory and nutritional properties, as well as its freshness. This non-thermal process allows meals to retain their texture, color, and flavor profile, while meeting the highest standards of food safety and quality. Designed for modern consumers who value wellness, convenience, and transparency in food.

Our SOLO Juice represents the essence of authentic and conscious nutrition. It is a 100% natural beverage, made exclusively from fresh fruits and vegetables, with no chemicals, preservatives, colorants, or artificial sweeteners of any kind. Each bottle contains only what nature provides, respecting the true flavor of the ingredients and their nutritional value.

Developed using carefully selected Colombian raw materials, SOLO Juice highlights the country’s agricultural richness through balanced and surprising combinations that connect with diverse audiences—from consumers seeking everyday wellness to those who value honest, distinctive flavor experiences.

We can design the products your Brand needs:

NO ADDITIVES

NO PRESERVATIVES

NO ADDED SUGARS

NO ARTIFICIAL COLORANTS

NO ADDED WATER

Today’s consumers demand foods and beverages with very specific characteristics: higher sensory and nutritional quality, no additives or preservatives, ready to eat, long shelf life, and 100% safe.

Thanks to the application of HPP (High Pressure Processing) technology, we achieve an exceptional balance between food safety, freshness, and shelf life. This non-thermal process preserves natural flavors, nutrients, and sensory characteristics. The result is a product that remains fresh as on the first day, with reliable quality.

In a market saturated with beverages and processed foods, our SOLO juices and ready meals stand out as a unique proposition that integrates technology with natural ingredients, responding to global trends of health, transparency, and responsible consumption.

A non-thermal food and beverage preservation method (5°C–20°C) that extends shelf life while preserving the characteristics of fresh products and ensuring food safety.

HPP maintains the properties of fresh products for several weeks or even months.

Today’s consumers demand food and beverages with very specific characteristics: higher sensory and nutritional quality, no additives or preservatives, ready to consume, extended shelf life, and 100% safety.

Maintaining original freshness for up to 3 months is possible thanks to HPP technology.

Ongoing innovation and creative capability.

HPP is a non-thermal food and beverage preservation method (5°C–20°C) that extends shelf life while preserving the characteristics of fresh products and ensuring food safety.

HPP maintains the properties of fresh products for several weeks or even months. Today’s consumers demand food and beverages with very specific characteristics: higher sensory and nutritional quality, no additives or preservatives, ready to consume, extended shelf life, and 100% safety. Preserving original freshness for up to 3 months is possible thanks to HPP technology.

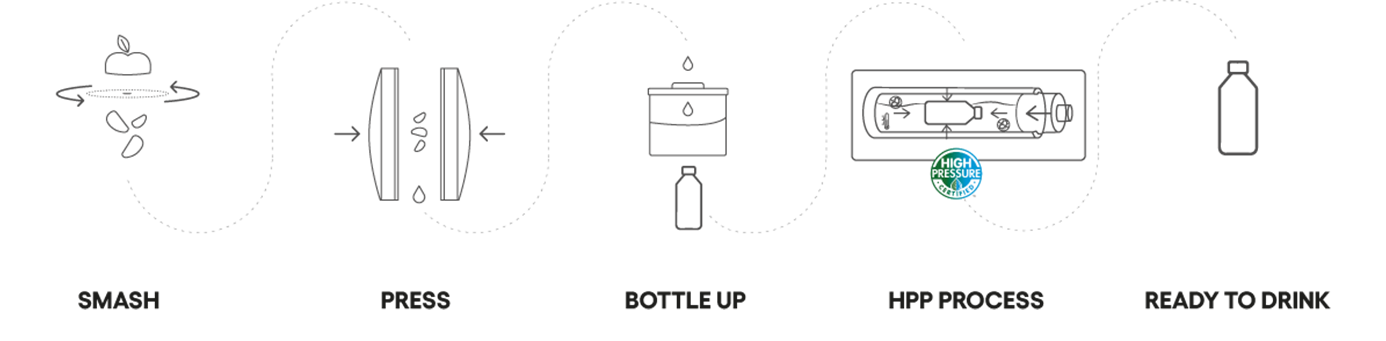

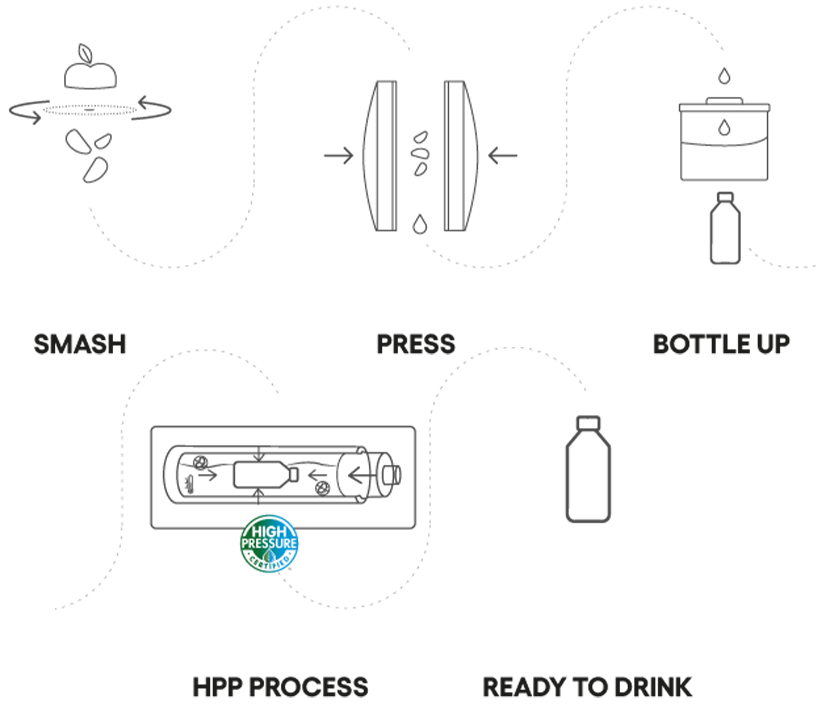

cold press

Cold-press technology is a process in which fruits and vegetables are crushed and pressed against a mesh basket, separating the fiber from the juice. When fruits or vegetables are processed using the cold-press method, their nutrients are preserved almost intact.